What is CFM?When selecting and evaluating air compressors, it's essential to understand key performance metrics such as discharge pressure, flow rate and rated power. Each of these metrics provides valuable insights into the compressor's capabilities and suitability for different applications.

Discharge pressure is a critical factor in air compressor performance, indicating how much pressure the compressor can generate. This metric is commonly measured in various units depending on regional preferences:

Bar: Widely used in Europe, 1 bar is equal to 100 kPa or 0.1 MPa. It’s approximately 1.0197 kg/cm² or 14.504 psi.

kg/cm²: Common in Asia, this unit is nearly equivalent to bar. For example, 1 kg/cm² is approximately 0.981 bar.

MPa (Megapascal): Commonly used in scientific contexts, 1 MPa equals 10 bar or 1000 kPa. It is a higher-pressure unit ideal for industrial applications.

kPa (Kilopascal): 1 kPa equals 0.01 bar or 0.145 psi. It's often used in low-pressure systems.

PSI (Pounds per Square Inch): Predominantly used in North America, 1 psi is approximately 0.0689 bar or 6.895 kPa.

Understanding these units and their conversions is crucial for ensuring that the compressor's discharge pressure aligns with the requirements of your tools and applications.

What is CFM? The flow rate of an air compressor indicates how much air it can deliver over a specific period. This metric is measured in several units:

l/min (Liters per Minute): Often used in smaller or European systems, this unit measures the volume of air delivered per minute.

m³/min (Cubic Meters per Minute): Common in industrial applications, 1 m³/min is equal to 1000 l/min or approximately 35.315 CFM.

CFM (Cubic Feet per Minute): Predominantly used in North America, CFM measures the volume of air moved per minute. For example, an air compressor rated at 30 CFM can move 30 cubic feet of air per minute.

Higher CFM indicates a greater airflow capacity, which is essential for operating multiple tools simultaneously or for applications requiring significant air volume.

While both CFM and m³/min measure air flow, they do so using different units—cubic feet versus cubic meters. This distinction means that identical flow rates will have different numerical values depending on the measurement unit used.

Additionally, regional preferences play a role in which unit is more commonly used. CFM is prevalent in North America, whereas m³/min is the standard in Europe, Asia, and other parts of the world.

Therefore, when choosing an air compressor, it's essential to be aware of the unit of measurement standard in your area and ensure it aligns with your equipment to maintain compatibility.

Rated power determines the energy consumption and overall power of the air compressor. The two main units are:

HP (Horsepower): A traditional unit, especially common in the U.S., where 1 HP equals approximately 0.7457 kW. Higher HP means more powerful compressors capable of delivering greater pressure and flow rates.

kW (Kilowatts): The metric equivalent of HP, widely used globally. Understanding the kW rating is crucial for ensuring that the compressor matches your electrical supply and can handle the required workload without overloading.

Selecting a compressor with the right power rating ensures efficiency and reliability in your operations.

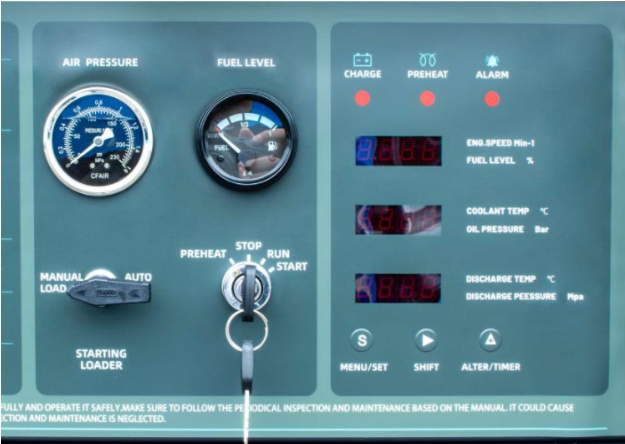

As you can see, understanding the metrics of CFM, kW, bar, and PSI is vital for selecting the right air compressor for your needs. At CFAIR, we pride ourselves on our commitment to providing high-quality, reliable air compressors that meet these critical performance standards. Our team of experts is dedicated to helping you find the perfect match for your specific requirements, ensuring that you get the most out of your equipment.

CFAIR recommends some popular products on the market based on customers' actual applications and offers customization services according to specific customer requirements. Simultaneously, CFAIR is committed to customizing machinery based on customers' specific needs. Whether customers require solutions tailored to special environments, specific flow rates, or customized pressure requirements, CFAIR provides personalized customization services, ensuring that products perfectly meet the practical engineering and application needs of customers. Through flexible customization options, CFAIR offers customers a broader range of choices to meet the requirements of different industries and application fields.